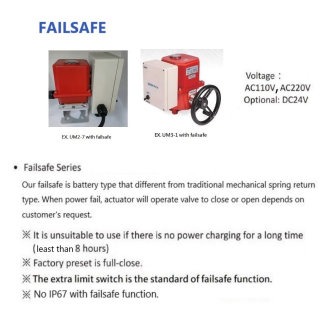

1. Basic type: focus on on/off type, 9Nm~3500Nm for different travel time, with failsafe function.

2. Fast type: focus on 100% duty cycle, 10Nm~50Nm fast open and close,

it’s able to continuously operate without overheat.

3. Smart type: focus on modulating, 75% duty cycle, 6Nm~2500Nm, with BLDC motor, modulating optional,

plug & play kit for backup power and failsafe optional function,

all of them can fit ball valves and butterfly valves and other quarter turn valves.

And one type linear valve actuator

For 60mm and 100mm stroke, thrust range is available for 1000N~10000N,

and with Bluetooth, backup power, failsafe, modulating, extra limit switch optional function.

It is available for gate valve, diaphragm valve, globe valve, and kinds of linear valves.

| Electric actuator type | Basic type | Fast Type | Smart type | Linear type |

| Item no. | UMS~UM-12 | UM-1-X~UM-2-5-X | UM1-N-D~UM12-N-D | UMB-N |

| Application valves | Quarter turn valves | Quarter turn valves | Quarter turn valves | linear valves |

| (ball valves, butterfly valves, dampers…) | (ball valves, butterfly valves, dampers…) | (ball valves, butterfly valves, dampers…) | (Gate valves, globe valves) | |

| Torque range (Nm) / Thrust range (N) | 10Nm~3500Nm | 10Nm~50Nm | 6Nm~2500Nm (rated torque) | 1000~6000N |

| Voltage | DC24V | DC24V/AC24V | DC24V | DC24V |

| AC110V | AC100~240V | AC100~240V | AC100~240V | |

| AC220V | ||||

| AC24V | ||||

| Acting method | ON-OFF | ON-OFF | ON-OFF | |

| Modulating | Modulating | |||

| Travel time / | depends on items | 1sec, 10sec | depends on items | depends on items |

| Duty cycle | Regulation 5 minutes | 100% | 30% | 30% |

| per travel | 75% | 75% | ||

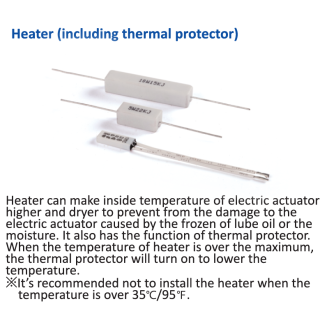

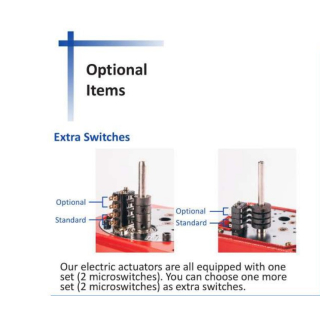

| Option function | Failsafe | Heater | Modulating Failsafe |

Modulating Failsafe |

| Extra limit switch | Heater | Heater | ||

| Heater | ||||

| Aluminum housing | Power backup | Power backup | ||

| RS-485 | RS-485 | |||

| Aluminum housing | Aluminum housing | |||

| Motor style | Induction (asynchronous) | BLDC | BLDC | BLDC |

| Example photos of electric actuators and connecting valves |  |

|

|

|

|

|

|

|