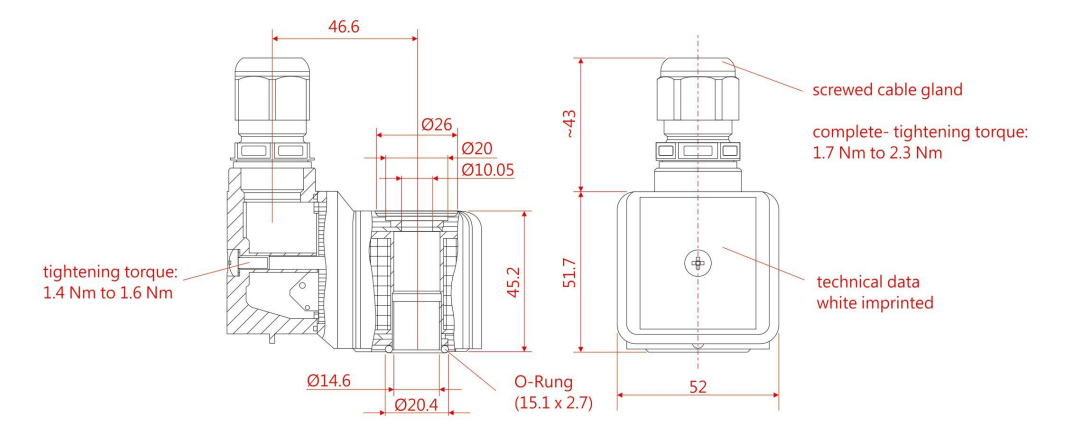

- Solenoid Coil System 13 ATEX with terminal box

Wideth: 52mm

Protection by encaps:

EX Ⅱ 2 G Ex e mb ⅡC T4, T6 Gb

EX Ⅱ 2 D Ex tb mb ⅢC T130°C, T80°C Db IP65, IP67

Connection Type: Terminal Box

Moulding Material: Thermoplastic

- General Data

Voltage tolerance: +/-10%

Ambient temperature: -40°C bis + 50°C/ + 60°C

Relative Duty Cycle: 100%

Insulation Class of Insulating Materials

According to DIN VDE 0580: F

Degree of Protection: IP65 / IP67

Type Examination Certificate: PTB 11 ATEX 2027 X

Imprint: nass magent (customer imprint possible)

- Drawing

- Specification

| MODEL | PIPE SIZE | CV | ORIFICE | FLUID TEMP. (ºC) |

Operating Pressure kgf-cm2 (bar) | VACUUM (Torr) |

Dimension (mm) |

Weight (kg) |

||||||

| WATER | AIR | STEAM | LIGHT OIL | GAS | L | H | D | |||||||

| PKW-10 | 3/8" | 2.4 | 15mm | -5ºC~+70ºC | 0~5 | 0~7 | 0~5 | 0~10-3 | 70 | 133 | 62 | 1.05 | ||

| PKW-15 | 1/2" | 4.5 | 15mm | -5ºC~+70ºC | 0~5 | 0~7 | 0~5 | 0~10-3 | 70 | 133 | 62 | 1.04 | ||

| PKW-20 | 3/4" | 8.6 | 20mm | -5ºC~+70ºC | 0~5 | 0~7 | 0~5 | 0~10-3 | 73 | 140 | 62 | 1.16 | ||

| PKW-25 | 1" | 12 | 25mm | -5ºC~+70ºC | 0~5 | 0~7 | 0~5 | 0~10-3 | 100 | 147 | 62 | 1.76 | ||

| PKW-35 | 1-1/4" | 24 | 35mm | -5ºC~+70ºC | 0~5 | 0~7 | 0~5 | 0~10-3 | 130 | 178 | 62 | 3.39 | ||

| PKW-40 | 1-1/2" | 28 | 40mm | -5ºC~+70ºC | 0~5 | 0~7 | 0~5 | 0~10-3 | 130 | 183 | 62 | 3.49 | ||

| PKW-50 | 2" | 48 | 50mm | -5ºC~+70ºC | 0~5 | 0~7 | 0~5 | 0~10-3 | 165 | 191 | 62 | 5.08 | ||

- Material

| PARTS | Coil | Tube | Spring | Core | Plug | Diaphragm | Valve Body |

| MATERIAL | NASS Explosion-proof Coil | Stainless Steel | Stainless Steel | Stainless Steel | Viton | NBR | Brass |

- Description

- PKW series is direct, multiplex, connected diaphragm, conductive, and normally close (NC) 2/2 solenoid valve

- Explosion-proof Protection Level: Ⅱ2 G Ex e mb ⅡC T4 Gb

- Waterproof Protection: IP67

- Able to be operated directly under low pressure

- Availability of fluid: water, air, light oil, gas, vacuum

- Acceptable for customization VITON, Silicone, EDPM (only available for PKW-20 and PKW-25)

- Cautions

- Before installation depressurize the piping system and clean internally.

- For the protection of the equipment install a strainer or filter suitable for the service involved in the inlet side as close to the solenoid valve as possible.

- Ambient temperature should be under 70ºC

- Operating temperature should be under 60ºC

- AC voltage tolerance: +/- 10%; DC voltage tolerance: +/- 1%

- All standard solenoid valve MUST be mounted vertically upright.

- Not suitable for fluid as below:

- Liquid status when it is at high temperature; solid status when it is cool.

- Corrosive fluid

- Seawater

- Viscosity over 20cst